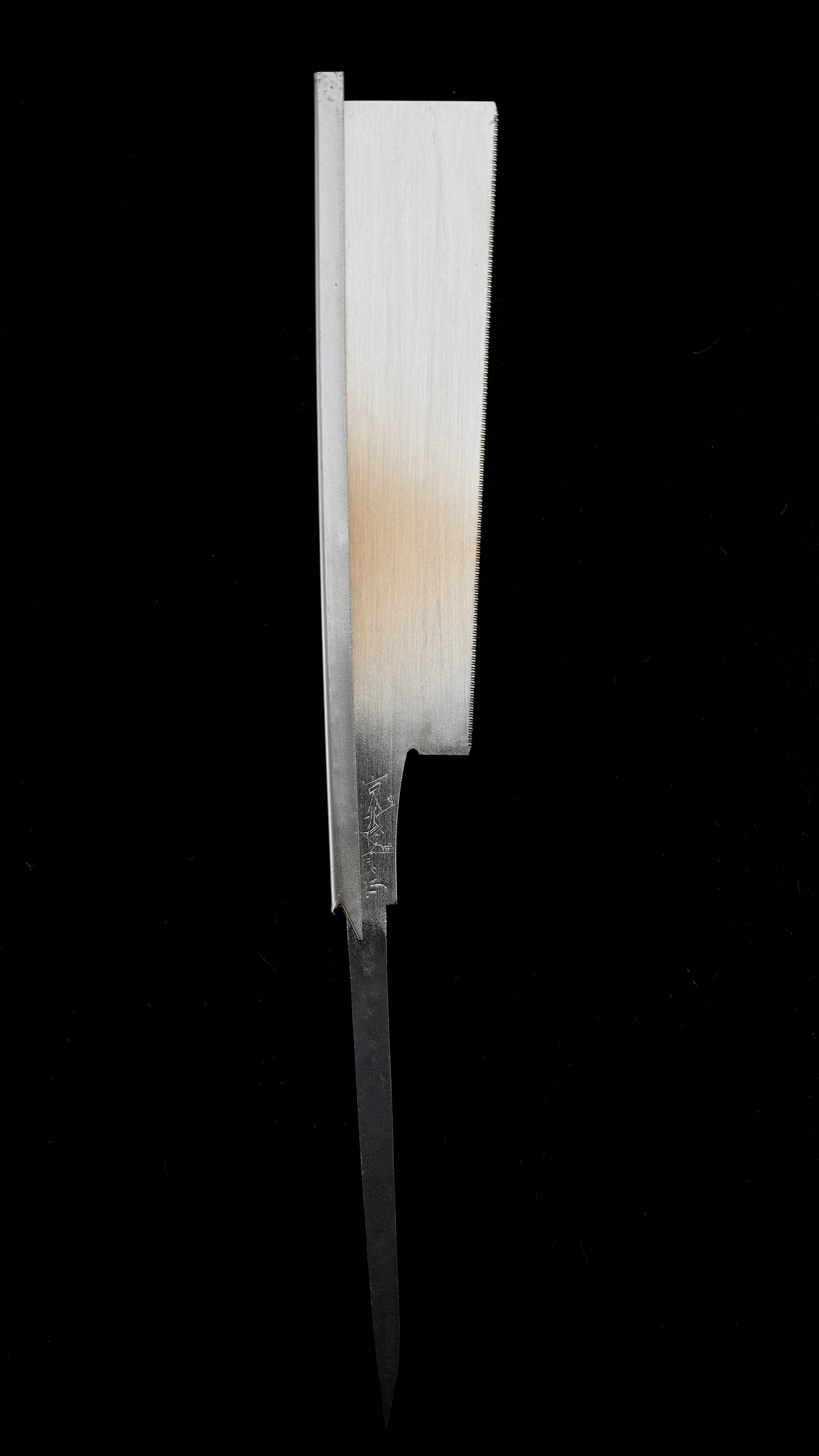

Douzuki Noko Japanese Precision Cross Cutting Hand Saw By Yamakuchi Sukezaemon - 240mm

Smith name: Yamakuchi Sukezaemon (山口介佐衛門, 1911~1975)

Steel: Carbon Steel

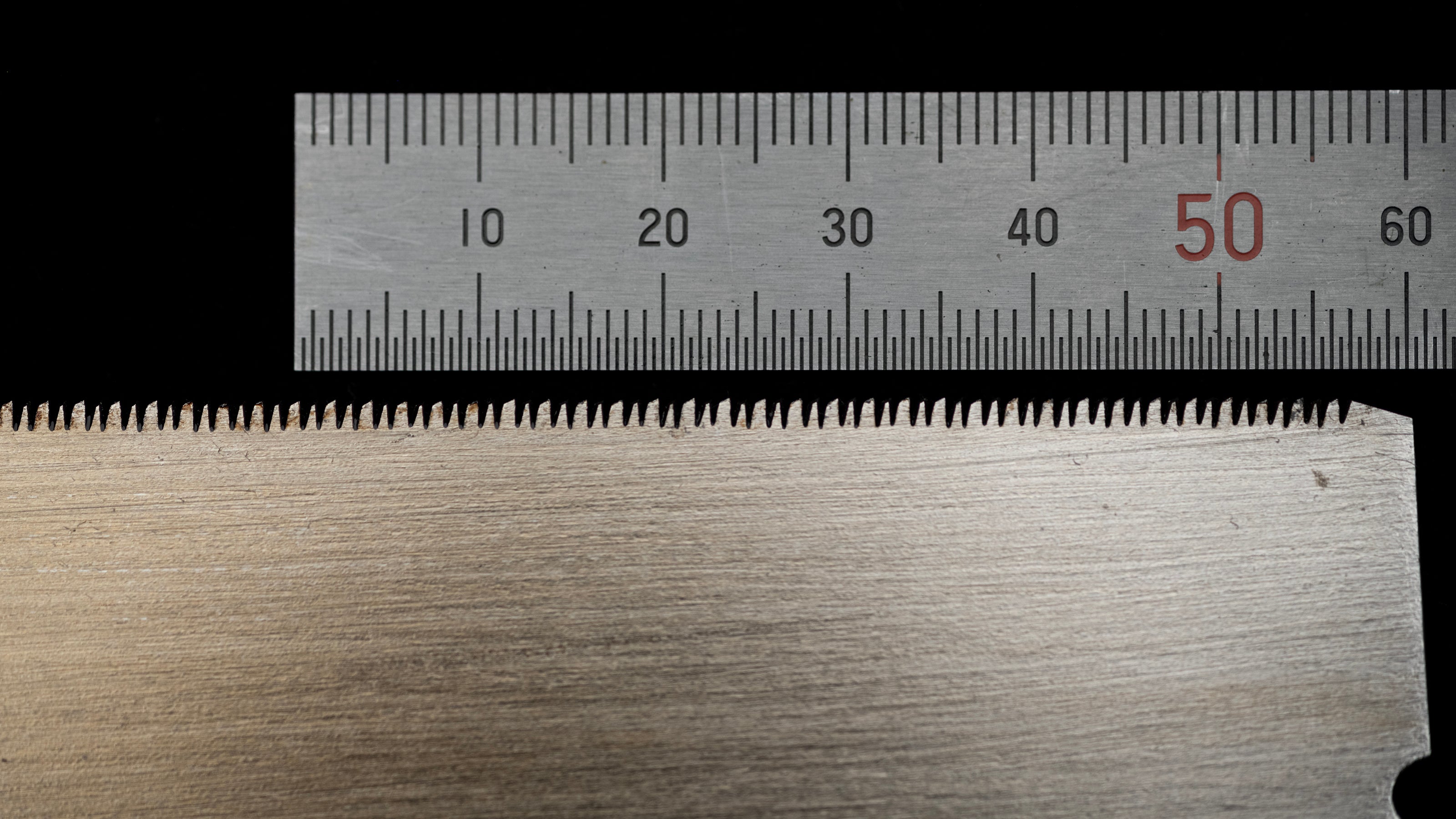

Cutting edge length: 240mm

Total length: 490mm

Blade thickness: about 0.25mm

Cutting Depth: about 45mm

Weight: 133g

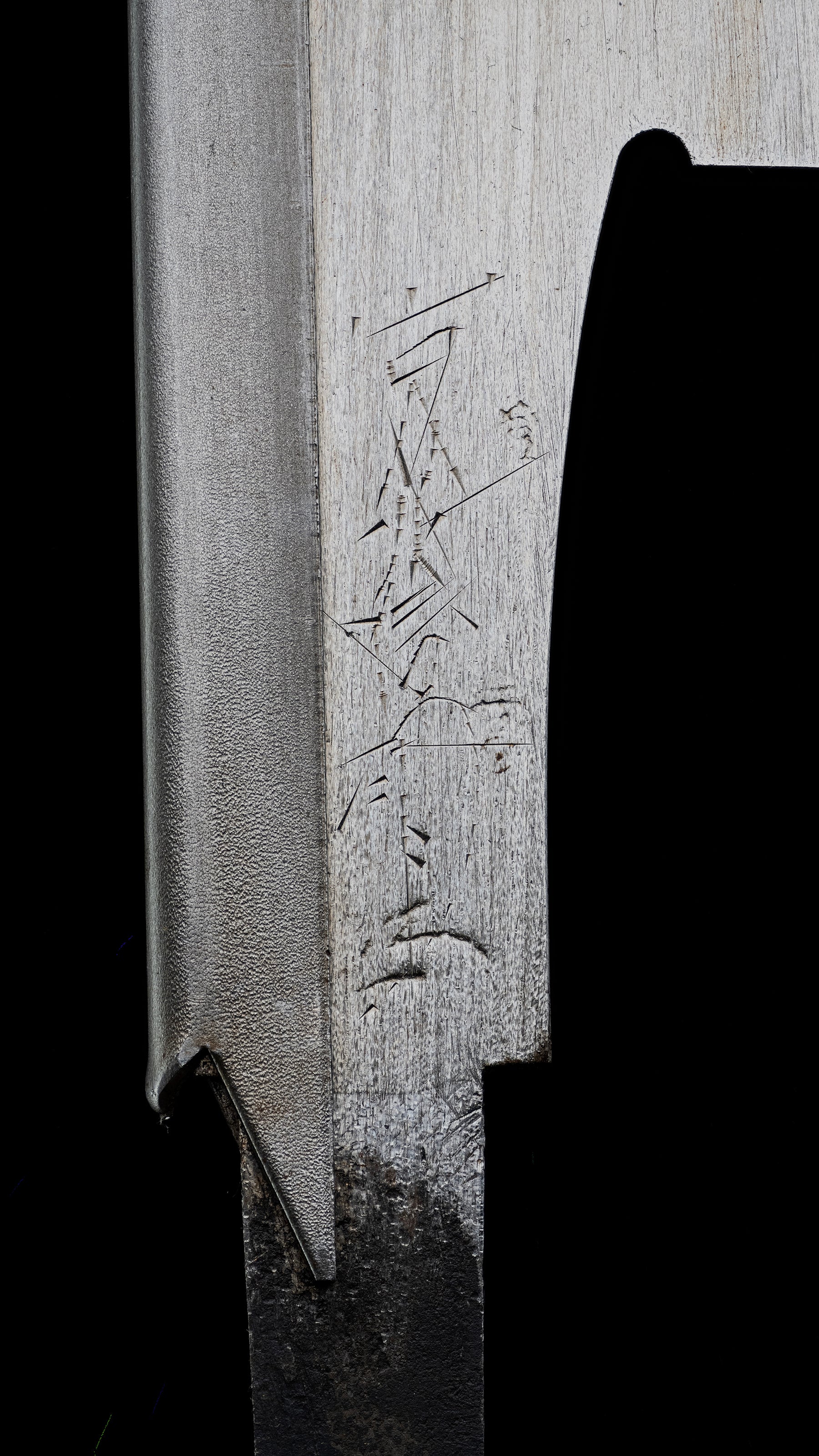

Blade sharpening and adjusting: Yamakuchi Sukezaemon

Manufacture Era: Before 1970s

Accessories:-

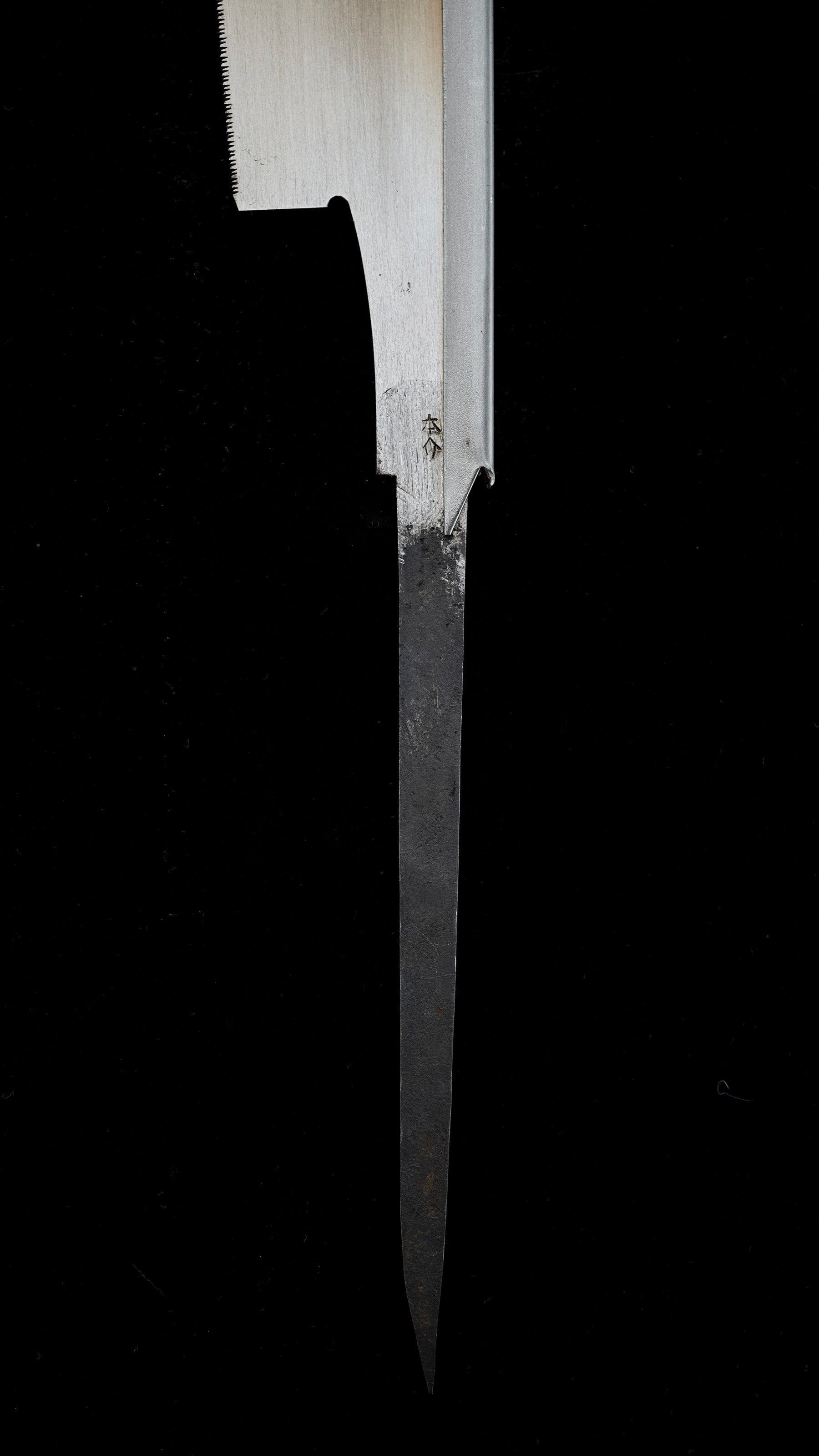

Additional Information: Unused. Known within the trade as a top-tier Japanese Dozuki noko, I found this saw at a specialist tools store in the Kanto region. After negotiating with the owner, he agreed to sell me this—the very last one in stock.

This saw has been exceptionally well-preserved and is in near-mint condition. Crucially, it has never undergone Metate (sharpening/tuning) by any other craftsman. It perfectly retains the original edge and finish directly from Blacksmith Yamaguchi.

I consulted Mr. Tsuchida regarding this saw, and he shared some key insights that are not mentioned in any publicly available online records. I would like to share those exclusive details with you here.

-

Technical Lineage

Yamaguchi's technique was most heavily influenced by Oba Shoichiro I (First Generation), despite the fact that Oba never officially accepted him as an apprentice. -

Steel

Unlike other blacksmiths who strictly adhere to specific grades like White Paper (Shirogami) No. 1 or No. 2, Yamaguchi did not limit himself to a fixed steel type. Instead, he would visit material suppliers regularly to personally select and test the steel before purchasing.While the specific batches varied, it is certain that he exclusively used carbon steel, never alloy steels like Blue steel (Aogami).

According to Mr. Tsuchida, the master hammer smith Kozaburo often encountered Yamaguchi at steel shops in Sanjo, testifying to his rigorous selection process. -

The Secret of "Nagagire" (Edge Retention)

According to Mr. Tsuchida, Yamaguchi aimed for a higher degree of hardness during the heat treatment process.

Naturally, despite this extreme hardness, the steel retains excellent toughness (tenacity) to prevent the blade from snapping—a balance similar to that of Kiyotada chisels, which are also renowned for their exceptional edge retention.

However, this hardness made the manual scraping process using the "Sen" tool incredibly labor-intensive. The hard steel created significant cutting resistance and caused the tool to slip easily, requiring immense skill and time to finish.

Furthermore, the tooth profile is designed to be more robust than the overly slender teeth commonly found on the market. This specific cross-cut tooth geometry was also favored and recommended by the master smith Miyano Tetsunosuke.

オプションを選択