Kanna Japanese Smoothing Plane Blade By Chiyotsuru Nobekuni - 65mm

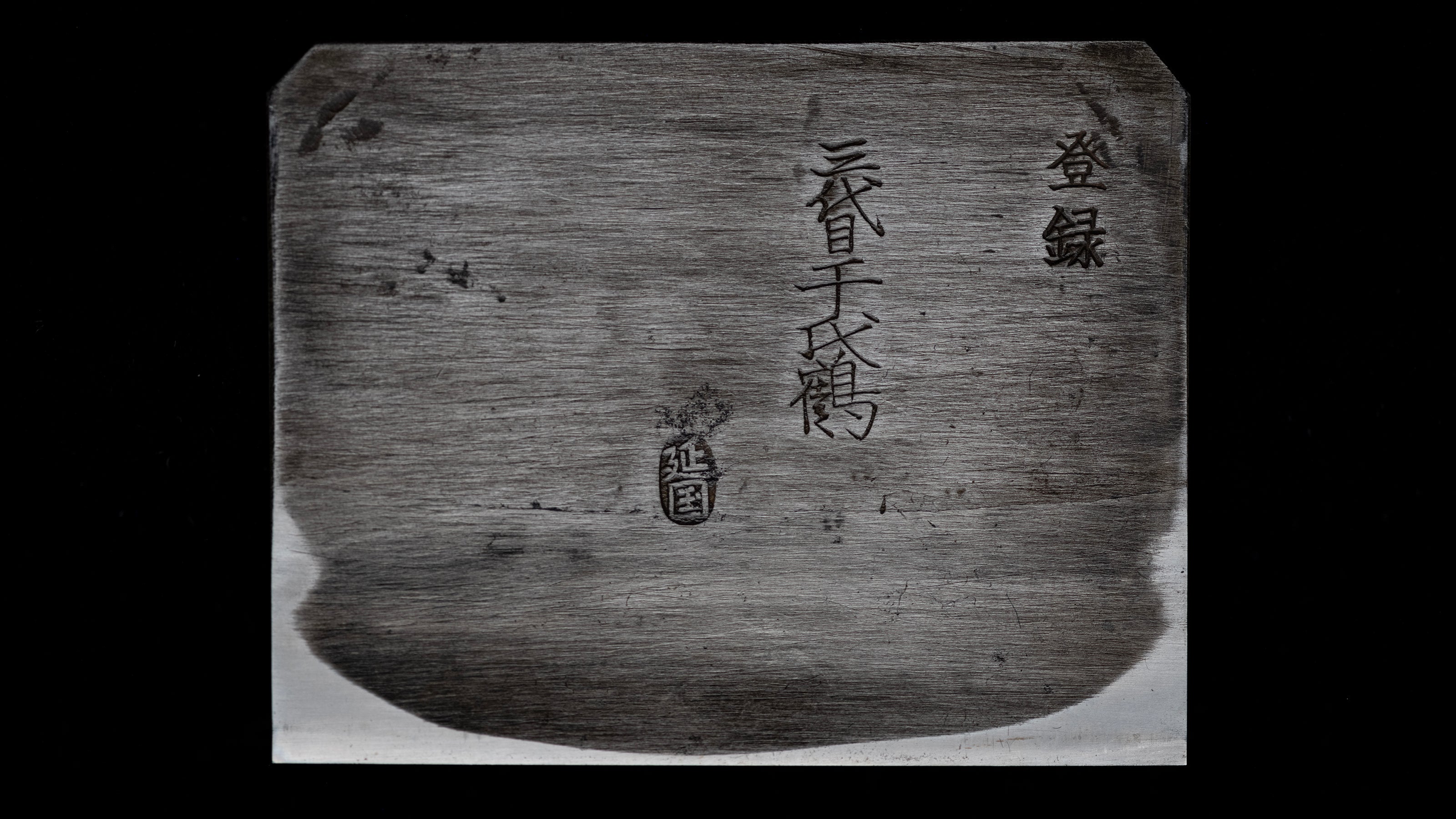

Brand name: 延國(Nobekuni)

Smith name: Ochiai Giichi & Ochiai Kazuyoshi

Steel: Swedish steel

Jigane: High quality Kamaji

Manufacturing number: No.7050

Blade Width: 65mm

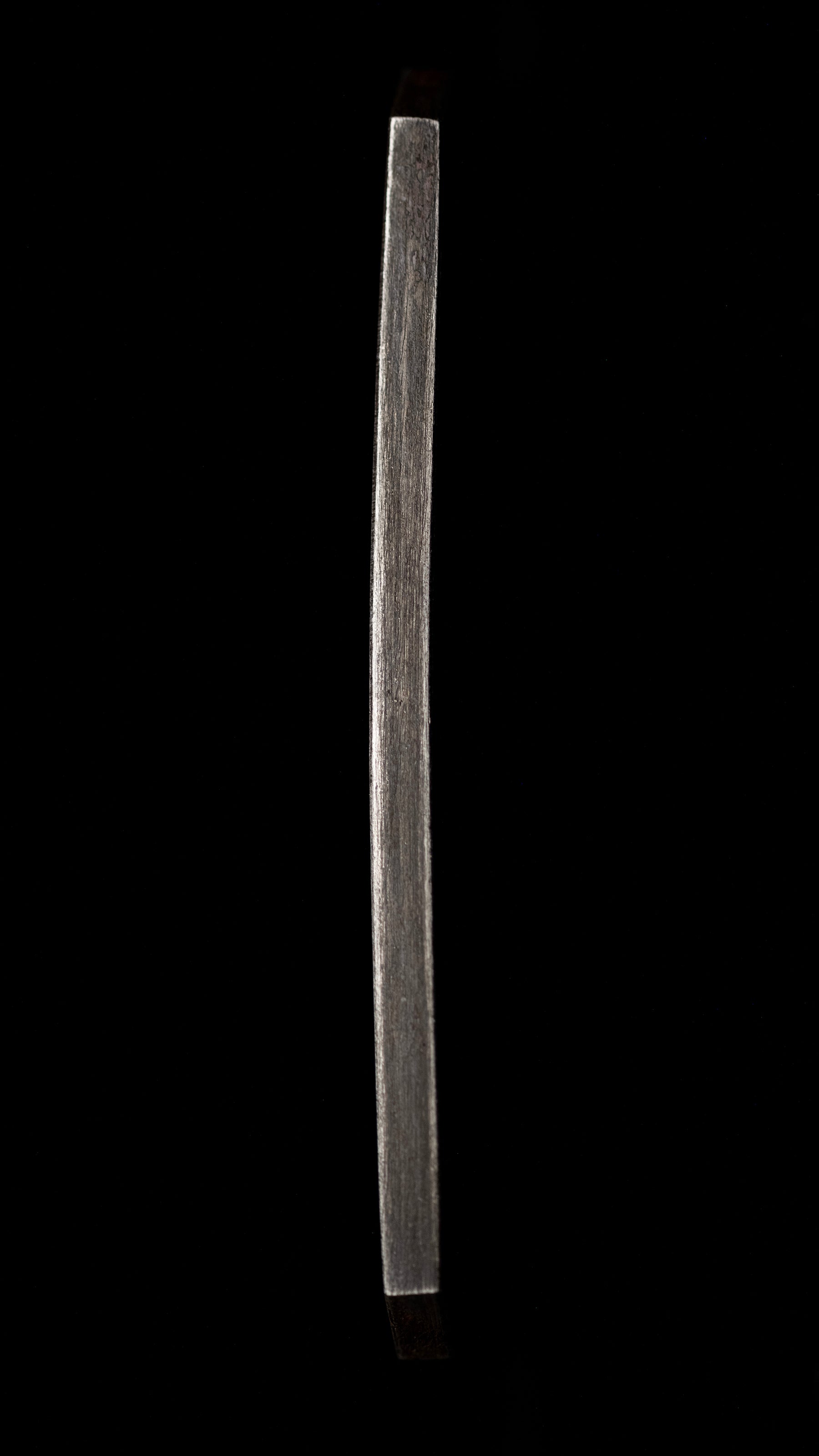

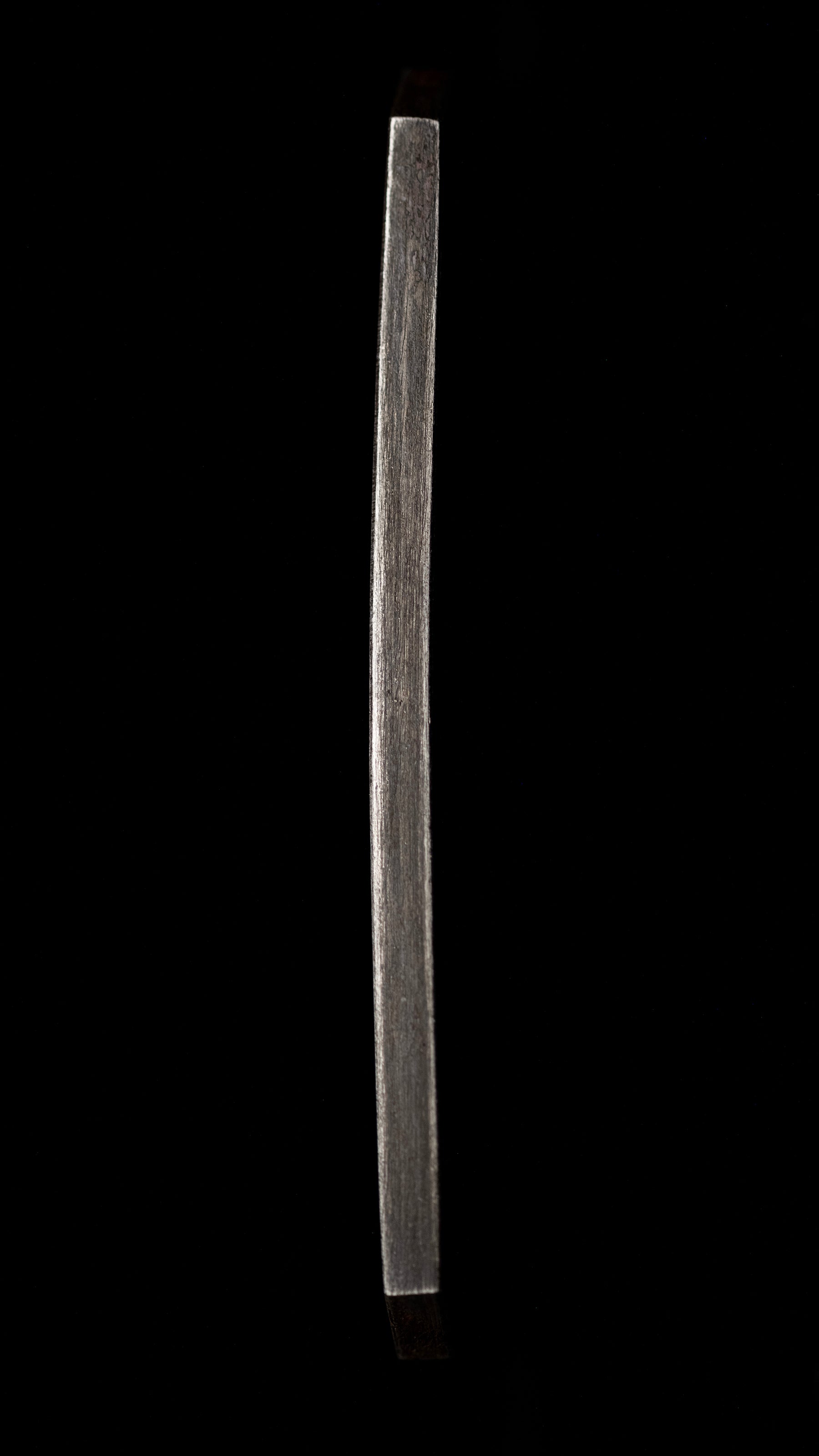

Blade length: 94mm

Blade Weight: 318g

Blade Angles: 27°

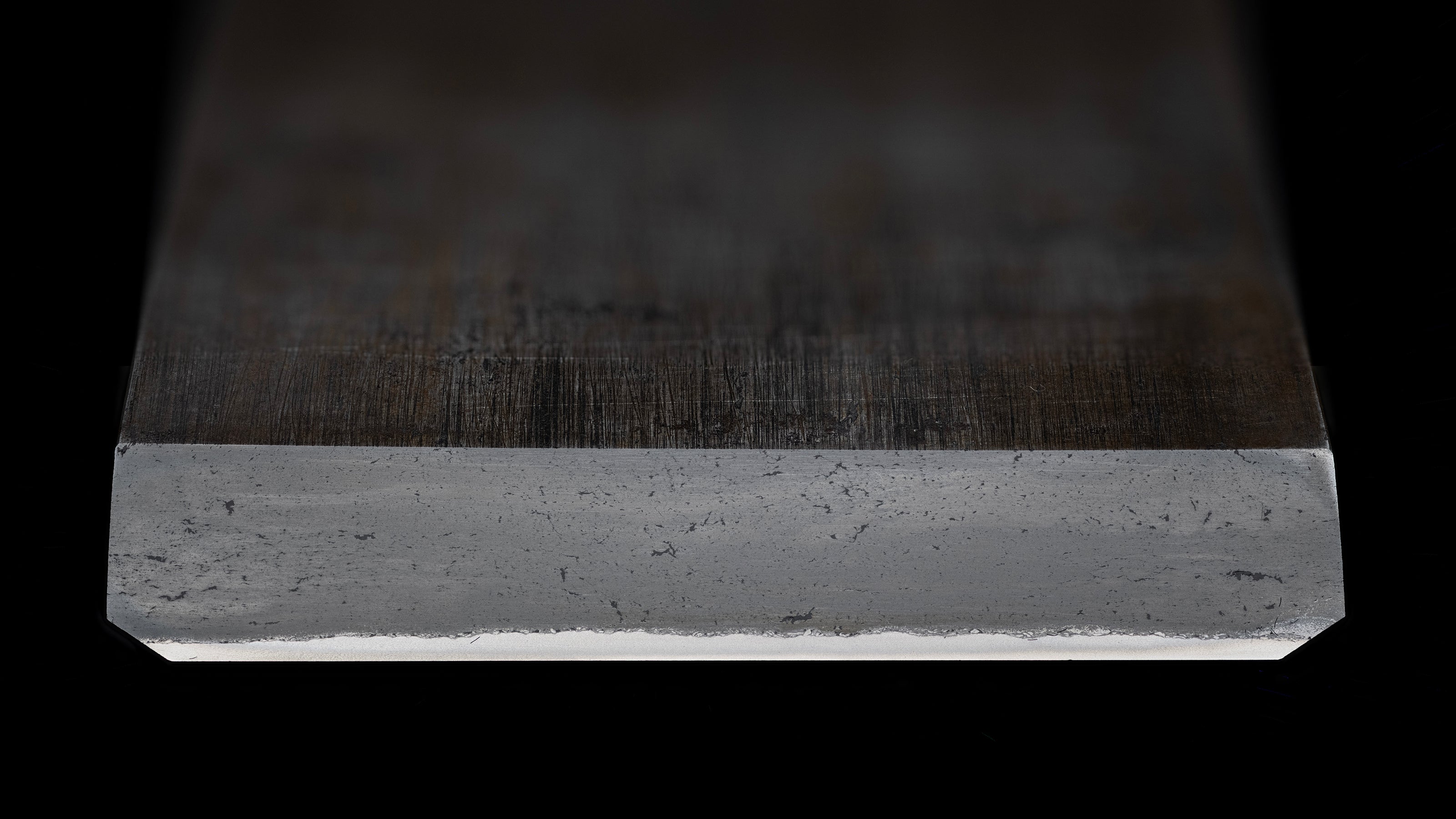

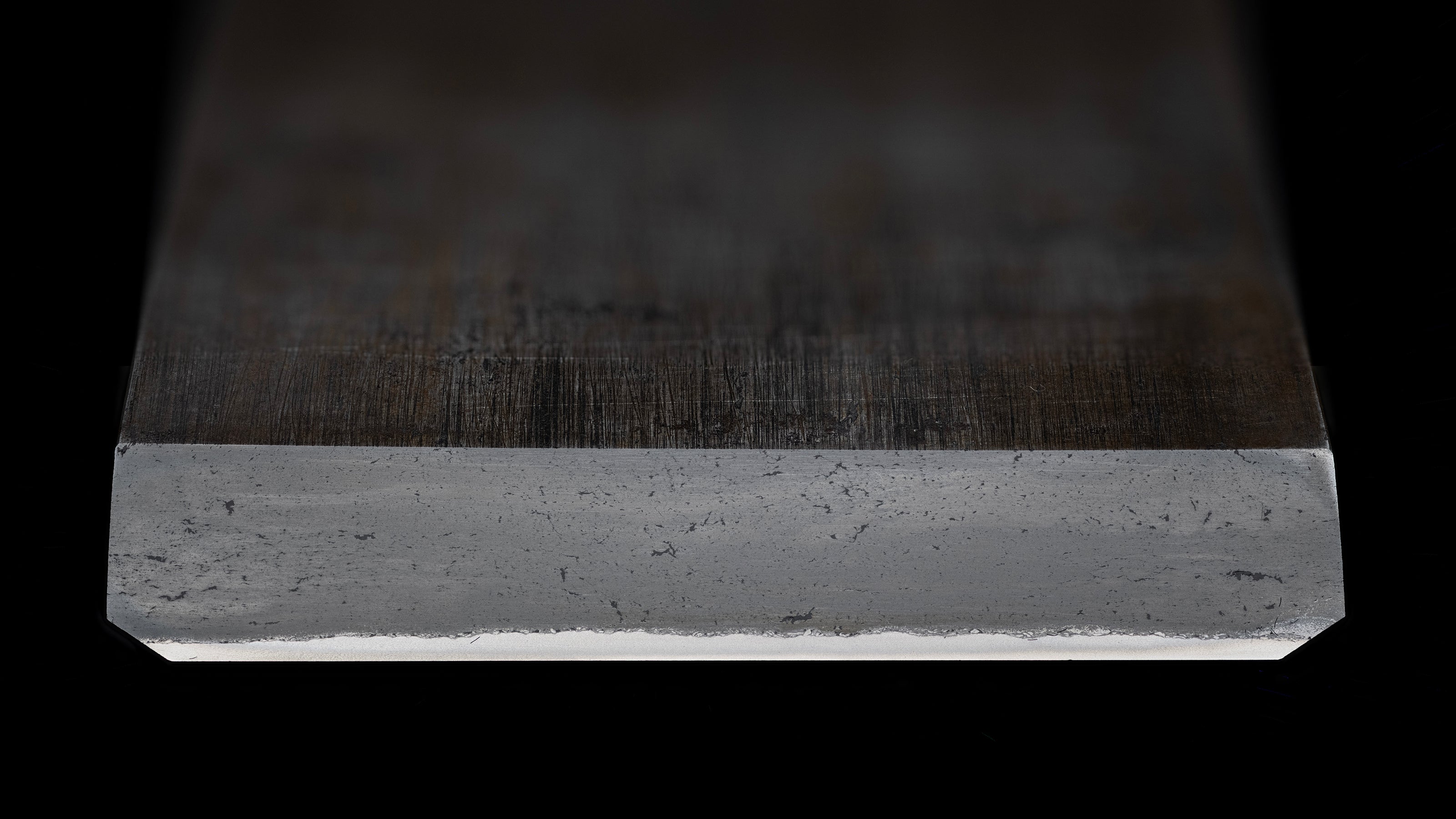

Blade thickness: Blade Bottom(about 6.4mm),Top of Blade(about 9.7mm)

Dai manufacture: Koyoshiya

Dai size(length, width, thickness): 290mm 81mm 36mm

Total weight: 1082g

Accessories: Special Nobekuni thin type Chip Breaker (About 2.5mm thick, if set properly, it can effectively reduce the resistance generated during cutting compared to thicker Chip Breaker)

Manufacture Era: December 28, 1977 (The number below the production number represents December 18, Showa 52)

Additional Information: Used, in good condition. Its wooden body is brand new.

I did some basic sharpening on the bevel of the blade. During this process, I felt the softness of the jigane part, similar to that of high-quality Japanese iron.

After Mr. Ochiai Yuichi retired in 1973, most of the third-generation Chiyozuru planes are made by Ochiai Uichi's sons, Ochiai Giichi (落合義一,the eldest son) and Ochiai Kazuyoshi (落合和吉,the second son). After 1987, Yoshiichi's health deteriorated and Kazuyoshi was the only one who continued to work in the blacksmith shop. Therefore, most of the third-generation Chiyozuru plane currently on the market are made by Ochiai Kazuyoshi.

From Tsuchida's books and conversations, I learned that the Ochiai Giichi was responsible for the forging and quenching stages, while the Ochiai Kazuyoshi was only responsible for the blade shaping stage. The Ochiai Giichi's forging and quenching skills were better, and after the Ochiai Giichi's retired, the quality of the younger brother's blades became a little unstable. Fortunately, the production year of this blade indicates that it was the work of the two brothers during their collaboration.

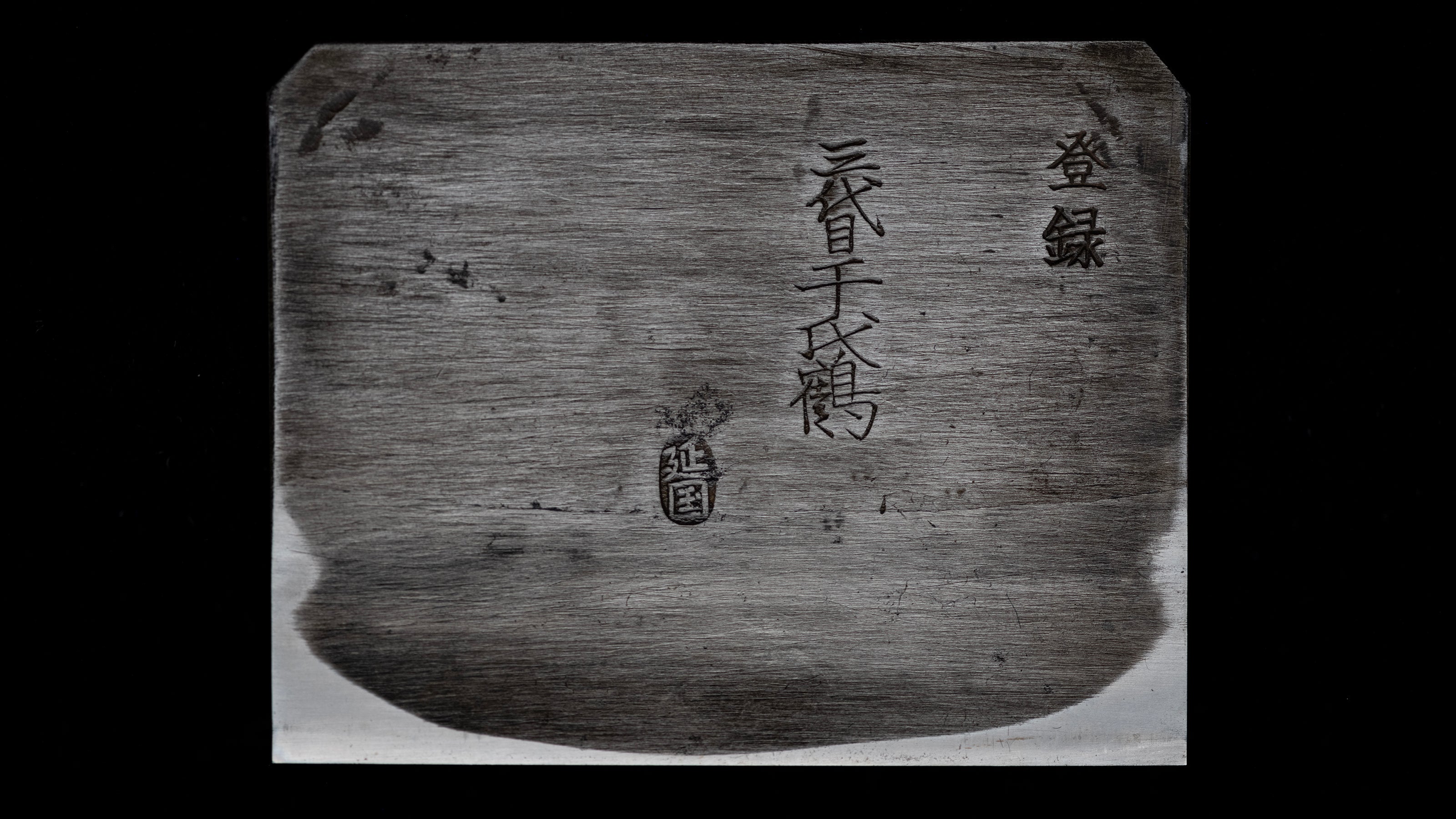

Tips on the mark on the blade:

1: The diamond mark on the right side of the fourth picture indicates that the steel is Swedish steel. If it is plum blossom-shaped, it is white steel. These two types of steel have similar properties. Mr. Tsuchida Noboru explained why Swedish steel is so common is because the raw material (the perfect thickness) makes forging easier, while the thicker raw material (white steel) requires the blacksmith to forge it thinner before forging the blade.

オプションを選択