Oire-Nomi Japanese Hand Made Bench Chisel By Second Generation Kiyotada - 42mm

Smith name: Shimamura Kouzaburo

Steel: White Steel

Blade width: 42mm

Blade thickness:

Classical Type: Blade Bottom(about 8.3mm),Top of Blade(about 5.0mm)

Ichihiro Type: Blade Bottom(about 8.9mm),Top of Blade(about 5.0mm)

Manufacture Era: Earlier than 1990s (according to carpenter’s memory)

Weight: 179g(Classical Type); 195g(Ichihiro Type)

Blade Angles: 29°

Total length: 209mm(Classical Type); 222mm(Ichihiro Type);

Neck length: 46mm

Blade length: 56mm

Types of wooden handles:Japanese White Oak (Ichihiro Type); Red Oak(Classical Type)

Accessories:—

Additional Information:

Two second-generation Kiyotada Oire chisels with high production precision. The two chisels came from two retired carpenters in Tokyo. The Ichihiro type (Unused, left in the first picture) was purchased by the carpenter from the Tsuchida store (Tsuchida Ichiro's era), and the place of purchase of the classic type (Lightly used, right in the first picture) is unknown.

The basic setting of the wooden handle of the Ichihiro type chisel and the sharpening of the blade are done by Mr. Tsuchida Ichiro. The grain direction of the wood handle of this chisel is installed according to the experience of Anaya daiku (Japanese hole maker). For details, please see my blog :『Factors affecting the orientation of radial and tangential sections when installing oak chisel handles — Wood shear strength parallel to the grain』

If you are interested in why there are two types of Kiyotada chisels, please refer to the last two chapters of my blog: 『Kiyotada』

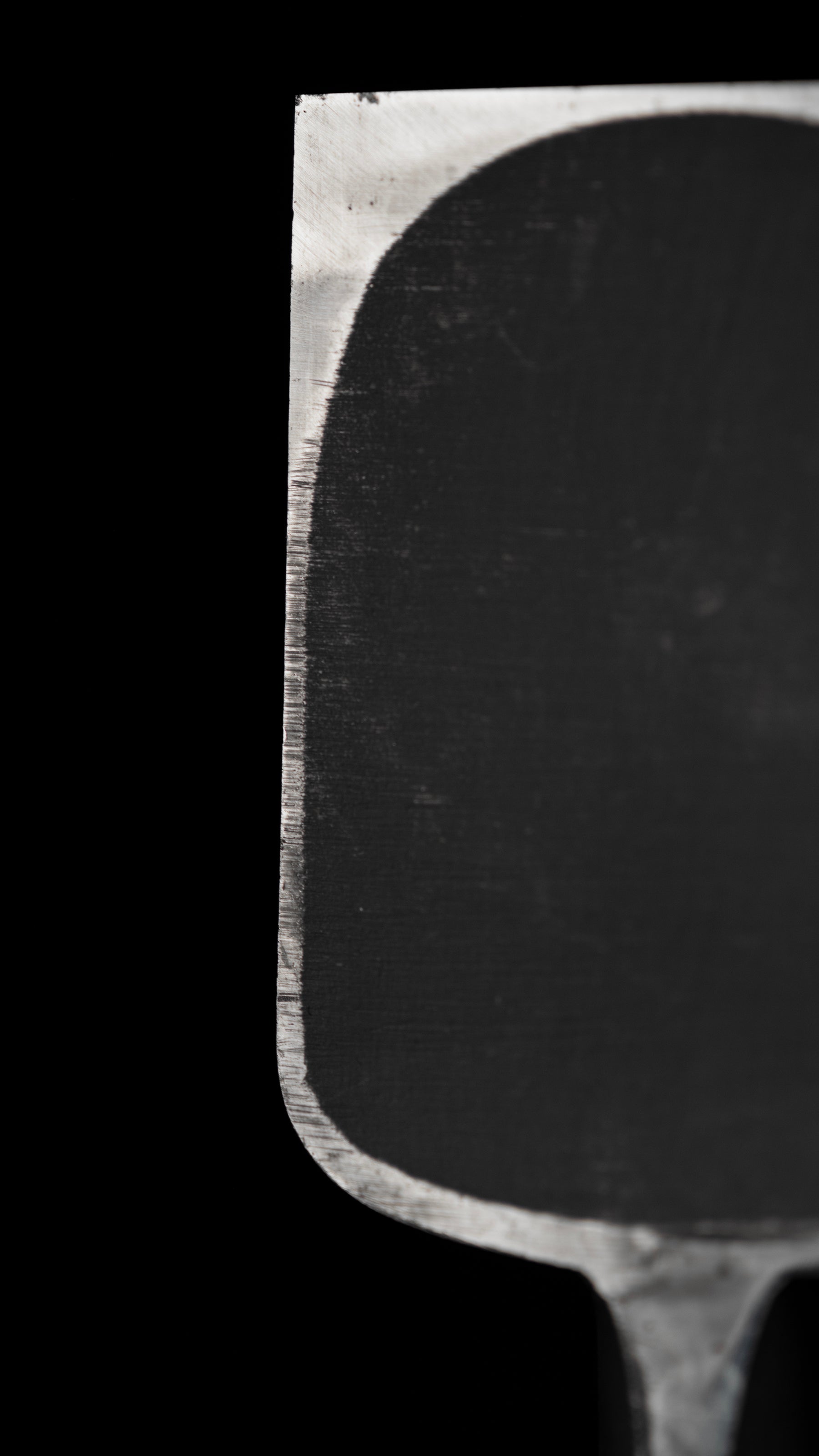

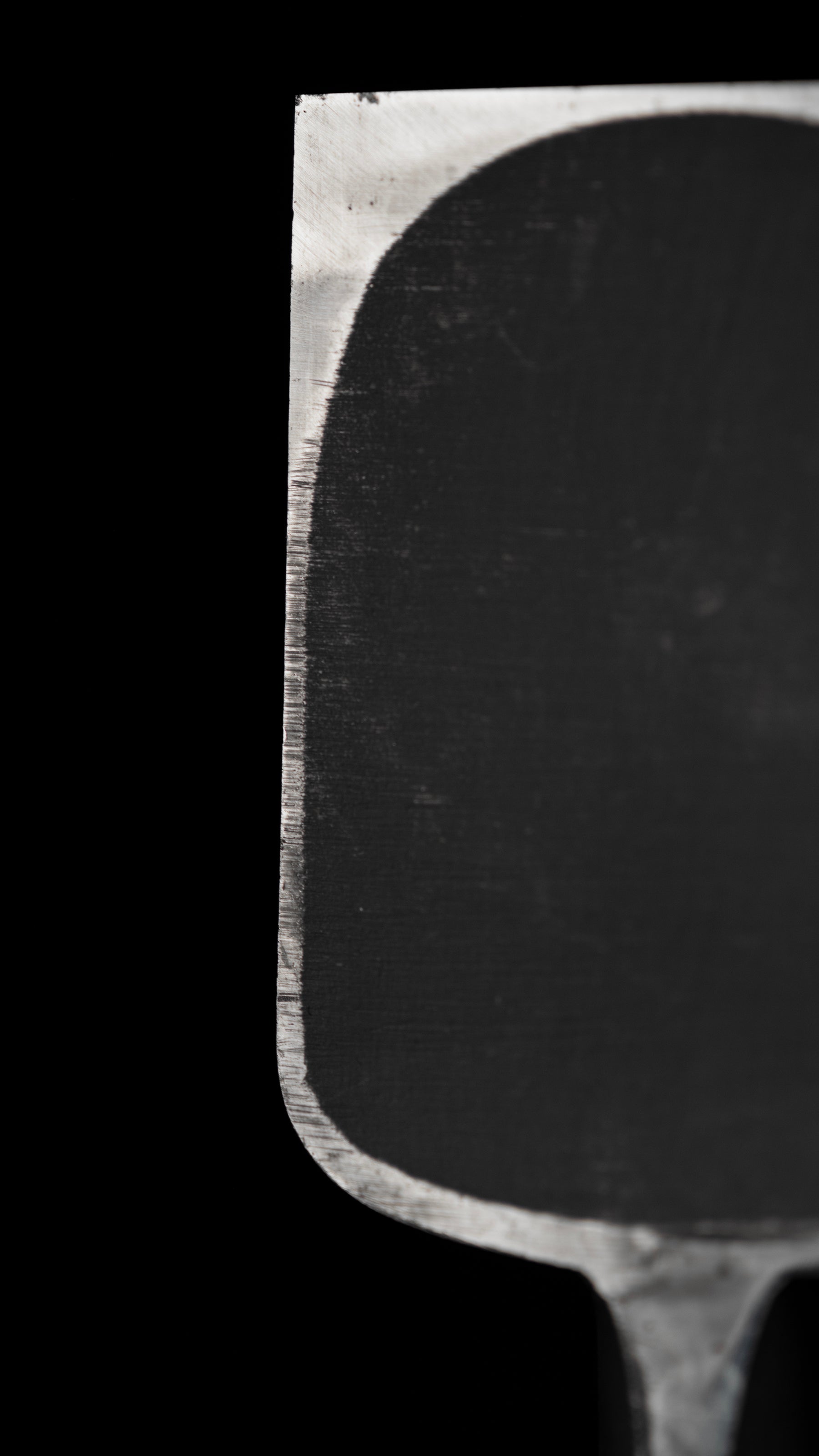

It is interesting to note that in most cases, the second generation Kiyotada chisels offered at Tsuchida store are of the classical type, and the chisels are thicker. As shown in the third picture, the chisels from Tsuchida store(the one above) have thicker blades at the bottom (about 0.5mm thicker).

It is strange why this Ichihiro type Kiyotada chisel is sold by Tsuchida store? I consulted Mr. Tsuchida Noboru and got the answer last month.

In order to ensure the efficiency of chisel production, the second-generation Kiyotada chisel blacksmith would produce chisel orders for different stores within the same period of time. Under the inertia of rapid production, the second generation of Kiyotada blacksmiths tend to have a uniform type when making the same batch of chisels.

If Kiyotada II received a complaint from Mr. Tsuchida when delivering an order of chisels to Tsuchida, the next batch of chisels would be made into the classical type; on the other hand, if he received a complaint when delivering to Suiheiya, the next batch of chisels would be made into the Ichihiro type. The second generation Kiyotada usually cycles between the requests of these two most important customers when making chisels in batches.

Choose options